Effect of Significant Machining Parameters Towards Turning Cutting Performance

DOI:

https://doi.org/10.37934/ard.113.1.110Keywords:

Two level factorial, aluminium alloy , ANOVA , MQL machining , cutting temperature , surface roughness , tool wearAbstract

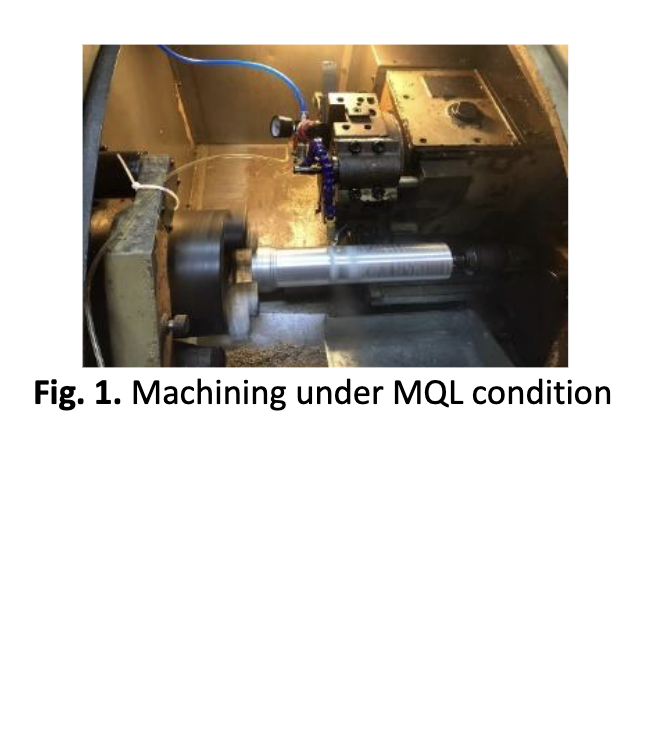

Selection of significant machining parameters before the cutting process is necessary to produce the best outcome in the machining performances. The use of cutting fluids due to their cooling capabilities helps in producing a good finished product. In the present paper, MQL equipment is developed by attaching it to the CNC lathe CT-200 machine. The two-level factorial is employed to study the performance effect of different machining parameters such as cutting speed, feed rate, depth of cut and air pressure. The paper deals with the turning of AA7075 under MQL conditions. From the experimental results, it is proposed that the optimal combination for minimizing cutting temperature from the present investigations is cutting speed at 400 m/min, feed rate at 0.1 mm/rev, depth of cut at 0.3 mm and air pressure at 0.3 MPa. The Pareto chart suggests that the selected factors are found to be significant and the corresponding interactions between cutting speed (m/min), feed rate (mm/rev), depth of cut (mm) and air pressure (MPa) are also found to be significant. It is also concluded that the effect of lubrication condition is more followed by the depth of cut, feed rate, air pressure and cutting speed for cutting temperature. But for surface roughness, the effect of lubrication condition is more followed by feed rate, depth of cut, air pressure and cutting speed. While for tool wear, the effect of lubrication condition is more followed by the depth of cut, air pressure, cutting speed and feed rate.

Downloads