The Effect of Fibre Loadings on the Mechanical and Thermal Properties of Sugar Palm/Waste Tyre Rubber Reinforced Polylactic Acid hybrid Composites via Fused Deposition Modelling

DOI:

https://doi.org/10.37934/ard.133.1.4459Keywords:

3D printing, mechanical properties, morphology, poly(lactic acid) sugar palm fiber, thermal analysis, waste tyre rubberAbstract

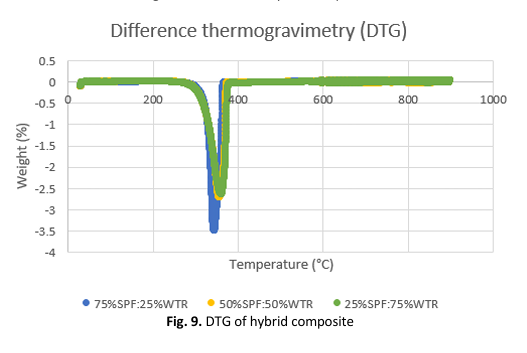

Sugar palm fiber (SPF) is a renewable, biodegradable, and eco-friendly resource, while waste tire rubber (WTR) enhances the properties of these composites. Poly(lactic acid) (PLA) serves as a promising biobased and biodegradable matrix material for these green composites. The mechanical and thermal properties of hybrid composite are crucial characteristics in the development of a hybrid composite Fused Deposition Modeling (FDM) filament since the printing mechanism of FDM strongly depends on the heating and extrusion process. To enhance interfacial adhesion, WTR and SPF were treated with 6% NaOH and 3% silane, resulting in a composite formulation of 97.5% PLA and 2.5% SPF/WTR. Three different fiber loadings were assessed: 75% SPF:25% WTR, 50% SPF:50% WTR, and 25% SPF:75% WTR. The filaments produced using a twin-screw extruder were utilized to 3D print tensile specimens according to ASTM D638, impact specimens according to ASTM D256 and the test of Thermogravimetric Analysis (TGA). The results indicated that the 75% SPF:25% WTR fiber loading achieved the highest mechanical properties for tensile strength of 37.89 MPa and appropriate that 25%SPF:75%WTR fiber loading achieved the highest mechanical properties for impact strength of 4.3 KJ/m2. Scanning electron microscopy (SEM) analysis also has been studied. The TGA test displayed similar thermal degradation patterns, suggesting that the ratio of components does not significantly alter the overall thermal stability of the composites. This enhanced performance is attributed to improved interfacial adhesion between the treated fibers and the PLA matrix, along with a uniform distribution of fibers throughout the composite. These findings suggest that sugar palm and waste tire rubber hybrid composites are viable, high-performance alternatives for the filament extrusion and printability of hybrid composite filaments.

Downloads