Development of a Filtration Tank for Biodiesel

DOI:

https://doi.org/10.37934/ard.134.1.99111Keywords:

WCO biodiesel, tank, mixing timeAbstract

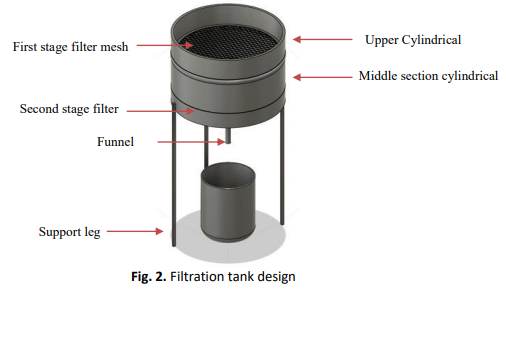

Waste cooking oil (WCO) has gained attention as a sustainable biodiesel feedstock due to its potential to reduce greenhouse gas emissions and support the global transition to eco-friendly energy sources. However, existing filtration tanks used for WCO processing are often expensive, bulky, and unsuitable for laboratory applications. To address these challenges, a laboratory-scale filtration tank prototype was developed, emphasising affordability, compactness, and ease of maintenance. The design drew inspiration from the user-friendly features of tiffin containers and bamboo steamers, enhancing stability and operational simplicity. Filtration and mixing time studies comparing mixing times of 30 and 120 minutes were used to assess the prototype's efficacy. In contrast to the 30-minute mixing time, which demonstrated incomplete blending, the results showed that the 120-minute mixing method produced a more homogenous and consistent biodiesel product with fewer indications of phase separation and better clarity. This implies that extended mixing improves biodiesel quality and intensifies the transesterification reaction.

Downloads