Modular Semi-Automated Assembly System with Real-Time Data Traceability for the Automotive Industry

Keywords:

MES, modular, traceabilityAbstract

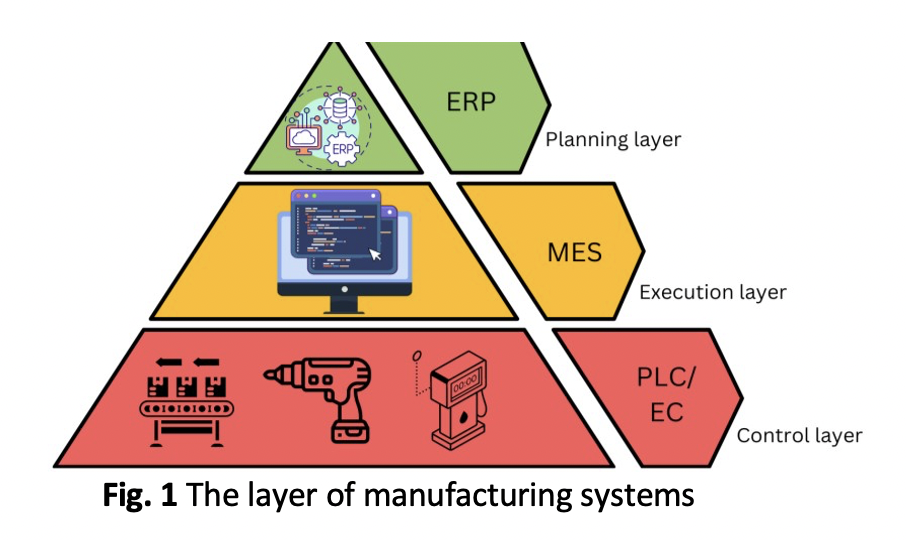

This paper presents the development and implementation of a modular, semiautomated assembly system with real-time data traceability for the automotive industry. The system integrates an automated two-level conveyor for material handling and palette recycling with an oil-filling machine to efficiently assemble work units. These components are interfaced with a centralized database and user-friendly production management web application, enabling real-time comprehensive data traceability and production control. Automated conveyor operations are monitored and controlled through an interactive web application that interfaces with PLC parameters using the MQTT protocol. The assembly process employs commercial torque controllers connected to a customized Java-based visual production guide, providing production personnel with real-time feedback on assembly operations. This integrated approach enhances operational efficiency, ensures accurate data tracking, and supports effective production management.

Downloads