Utilising Different Ratios of Plastic Waste Composition to Produce an Ecobrick as a Sustainable Building Material

DOI:

https://doi.org/10.37934/ard.131.1.7689Keywords:

plastic waste, ecobrick, compressive strength, drop test, flexural strength, ecobrick applicationAbstract

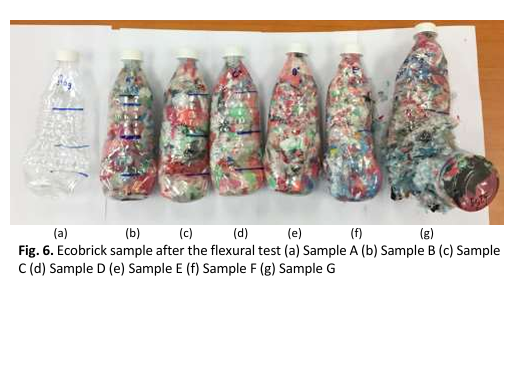

One of the most important building materials in construction is brick. Nevertheless, the production of brick brings more disadvantages than advantages to the environment and human health. Ecobrick has been identified as one of the tools that can be used as a sustainable building material in construction. In general, an ecobrick is a recycled Polyethylene Terephthalate (PET) plastic bottle filled with mixed inorganic waste such as used plastic, packaging or other wastes to a set density. The aim of this research is to determine the best ratio of plastic waste in PET bottles to produce ecobrick as a construction material. This research was conducted to evaluate the strength of the different density ratios of plastic waste in PET bottles in terms of compressive strength, drop impact resistance and flexural strength. A total of seven ecobrick samples with density ratios of 0 g/ml, 0.15 g/ml, 0.25 g/ml, 0.35 g/ml, 0.45 g/ml, 0.55 g/ml and 0.65 g/ml were prepared. The samples were tested using compressive tests, drop tests, flexural tests and failure analysis. The tests revealed that the optimum density ratio of an ecobrick is 0.45 g/ml. Subsequently, 3-unit and 6-unit blocks were developed to test the strength of the ecobrick with a density ratio of 0.45 g/ml. This was done to investigate the feasibility of ecobrick as a construction material. The compressive strength for the 6-unit ecobrick was 9272.13 N while the compressive strength for the 3-unit ecobrick was 3649.03N. It can thus be concluded that a combination of ecobrick units provides greater compressive strength which makes it suitable as construction material.

Downloads