Enhancing Oxidation Resistance in Aluminum and Aluminum Alloy Through Lean Six Sigma Methodology

Keywords:

Oxidation, Aluminum and Aluminum Alloys, Lean Six Sigma, Process Improvement, Quality ControlAbstract

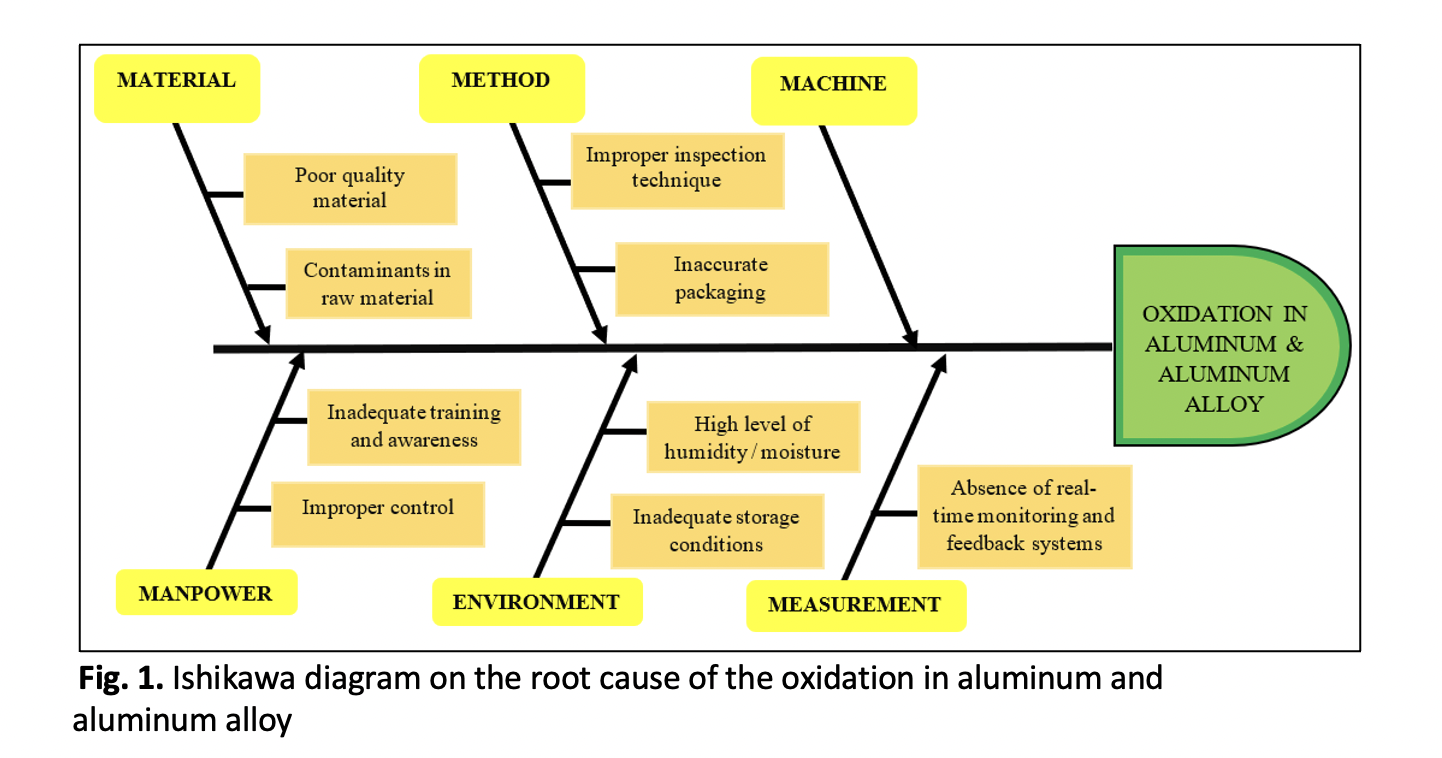

This research explores the enhancement of oxidation resistance in aluminum and its alloys through the utilization of Lean Six Sigma methodologies. The primary objective is to identify the root causes of oxidation in these materials and implement process improvements to bolster their resistance to oxidation. By employing Lean Six Sigma tools and techniques, the research aims to optimize manufacturing processes and elevate the quality of aluminum products. The study addresses the challenges associated with maintaining oxidation resistance in aluminum and its alloys, which can lead to material degradation and reduced product longevity. Through a thorough investigation of oxidation mechanisms, environmental influences, alloy compositions, and surface treatments, the research aims to mitigate these challenges and enhance the overall performance and durability of aluminum materials. Results and discussions from the study underscore the efficacy of Lean Six Sigma in enhancing oxidation resistance in aluminum and its alloys. The analysis provides valuable insights into the factors influencing oxidation and emphasizes the role of quality improvement methodologies in material science and manufacturing processes. The study's findings have implications for advancing material science, promoting sustainability, and improving quality assessment in the manufacturing sector. In conclusion, this research highlights the importance of continuous improvement and innovation in material engineering. By applying Lean Six Sigma methodologies to address oxidation challenges, the study contributes to the progression of material science, sustainability initiatives, and quality enhancement in aluminum product manufacturing. The outcomes offer practical implications for enhancing competitiveness, market positioning, and environmental stewardship in the production of aluminum-based materials.

Downloads