Part Detection Model for Aerospace Manufacturing Quality Control using Convolutional Neural Networks

DOI:

https://doi.org/10.37934/ard.133.1.110Keywords:

Part detection, convolutional neural networks, deep learning, quality controlAbstract

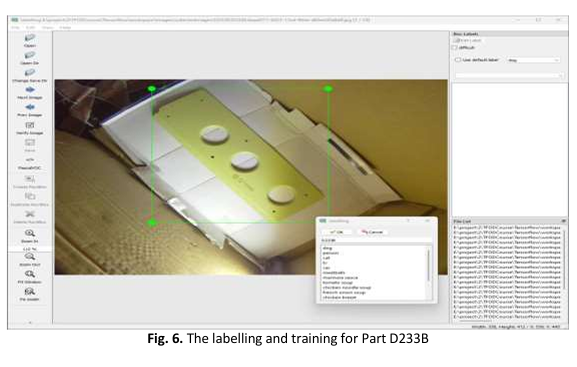

Ensuring the precision and efficiency of quality control processes in the aerospace manufacturing industry is critical to remain competitive. This paper presents an advanced approach to address the challenge of identifying and categorising similar aerospace components quality effectively using Artificial Intelligence’s computer vision and convolutional neural network’s deep learning technique to resolve the issue of parts misclassification. Specifically, in the development of a comprehensive database for object detection using Phyton programming and tailored to the unique requirements of the aerospace industry under study. The methodology involved collecting a diverse dataset comprising 50 images per class, annotated with bounding boxes and class labels, covering a pilot of D232B and D233B machining parts. The dataset is partitioned into training, validation, and test sets to facilitate the model training and evaluation. Furthermore, tools for managing and accessing the dataset were introduced, including the interface for image labelling. Leveraging on TensorFlow, the effectiveness of this approach was able to be tested in training the part detection model with 94% accuracy for part D233B and 97% accuracy for part D232B, showcasing its suitability for real-world aerospace manufacturing quality inspection applications. Overall, this project represents a significant advancement in improving quality inspection process in the aerospace industry, offering a valuable approach for enhancing efficiency and accuracy in component identification.

Downloads