Evaluation of Egg Packaging Cushioning Systems Implemented with Lean Design Principles

DOI:

https://doi.org/10.37934/ard.133.1.7079Keywords:

Egg, cushion packaging, lean design, free-fall drop testAbstract

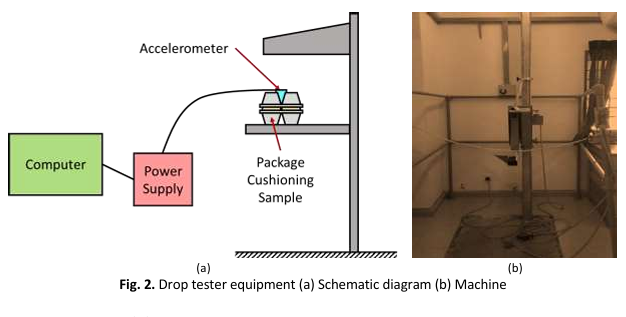

Proper packaging is critical to ensure safe and efficient distribution in the egg industry. Packaging systems must be designed to meet safety standards and customer requirements. This study focuses on evaluating the performance of cushion packaging for eggs using the lean design approach to select the most suitable packaging method. Given the fragility of eggs, which are highly susceptible to damage from impacts and surfaces, the study compares the effectiveness of three cushioning materials: polyethylene terephthalate (PET), high-impact polystyrene (HIPS), and moulded pulp cartons. Free-fall tests were conducted at various heights and orientations (flat top and flat bottom), with peak acceleration (GP) data recorded using an accelerometer and displayed via TP3 software. The results indicated that moulded pulp cartons outperformed PET and HIPS in vibration resistance and durability, maintaining product integrity even at a maximum height of 5.5 ft. The findings suggest that moulded pulp cartons offer the best cushioning solution, thanks to their excellent energy absorption properties, minimizing the risk of product damage during transport.

Downloads