Production Process Improvement Towards Lean Process Effectiveness using FlexSim Simulation Software

DOI:

https://doi.org/10.37934/ard.132.1.5265Keywords:

Lean manufacturing, industrial revolution 4.0, simulation, FlexSimAbstract

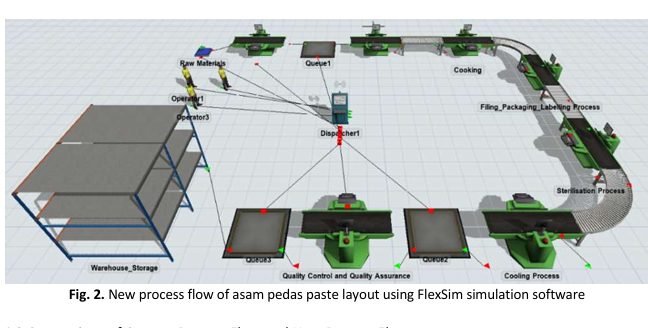

Lean involves optimizing entire value streams to minimize waste and enhance customer value in production practices. Process improvement encompasses the identification, analysis and enhancement of existing business processes to optimize performance and align with best practice standards for a company's products or services. Companies face the imperative of increasing production to meet demand per day. The challenges include enhancing the process effectiveness in the production line. Process effectiveness measures a process's ability to produce desired results, evaluated qualitatively. FlexSim integrates simulation, artificial intelligence, three-dimensional computer image processing and data processing technology. The research objectives include identifying the operational process flow in the study company, proposing a new production process flow using FlexSim simulation software and evaluating the process flow for reducing lead time as part of process improvement. This research adopts a qualitative method, collecting data through observation and interviews. This research helps companies to increase the efficiency and effectiveness of their productivity. The data is analysed using simulation software, focusing on production process improvement to enhance process effectiveness in the PMI's company. The study's outcome reveals a 19.92% reduction in lead time achieved by consolidating processes and eliminating waste, such as waiting time, transportation and product motion. This reduction translates to cost savings and increased profitability, highlighting the positive impact of the implemented changes on the overall performance of the company.

Downloads