Enhancing Manufacturing Productivity through Refined Work-Study Techniques: A Critical Review of Allowance Factors in Time Study

DOI:

https://doi.org/10.37934/ard.142.1.177195Keywords:

Work measurement, allowance factors, time study, standard time, manufacturing productivity, work-study techniquesAbstract

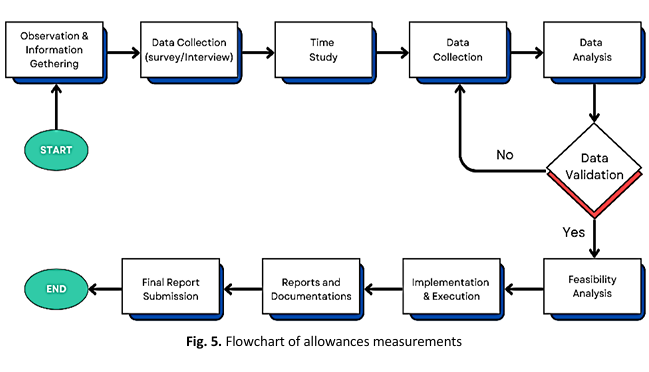

This systematic review examines the critical role of allowance factors in enhancing work measurement accuracy within mechanical and industrial engineering domains. The study addresses inconsistencies in understanding and implementing allowances across various manufacturing and production environments. Through a comprehensive analysis of extant literature and industry practices, this research categorizes and evaluates the impact of diverse allowance types on productivity and operational efficiency in engineering settings. The investigation encompasses three primary allowance categories: constant (e.g., personal needs, basic fatigue), variable (e.g., abnormal posture, environmental factors), and special (e.g., unavoidable delays, policy-based considerations). These allowances are analyzed for their application and impact in industrial and mechanical engineering contexts. Based on the literature synthesis, a methodological framework for allowance determination and implementation is proposed. This framework comprises systematic observation, empirical data collection through time studies, statistical analysis, and validation processes specific to engineering applications. It aims to enhance the precision of allowance estimation in developing equitable work standards, influencing labor cost calculations, productivity metrics, and operational efficiency in manufacturing systems. This study highlights the importance of accurate allowance integration in work measurement methodologies for mechanical and industrial engineering. It provides a structured approach to allowance application, contributing to the advancement of work measurement techniques in complex manufacturing environments. Findings offer evidence-based recommendations for implementing robust allowance strategies, aimed at optimizing work measurement practices and fostering sustainable operational improvements. This research serves as a comprehensive resource for engineers and researchers seeking to enhance the accuracy and effectiveness of their work measurement methodologies. By synthesizing current knowledge and best practices in allowance factor application, this study bridges the gap between theoretical concepts and practical implementation, ultimately improving productivity and efficiency in manufacturing and production processes.

Downloads