Verification of Lattice Spring Model for Modelling Composite Material

DOI:

https://doi.org/10.37934/aram.97.1.16Keywords:

lattice spring model, particle method, Finite Element MethodAbstract

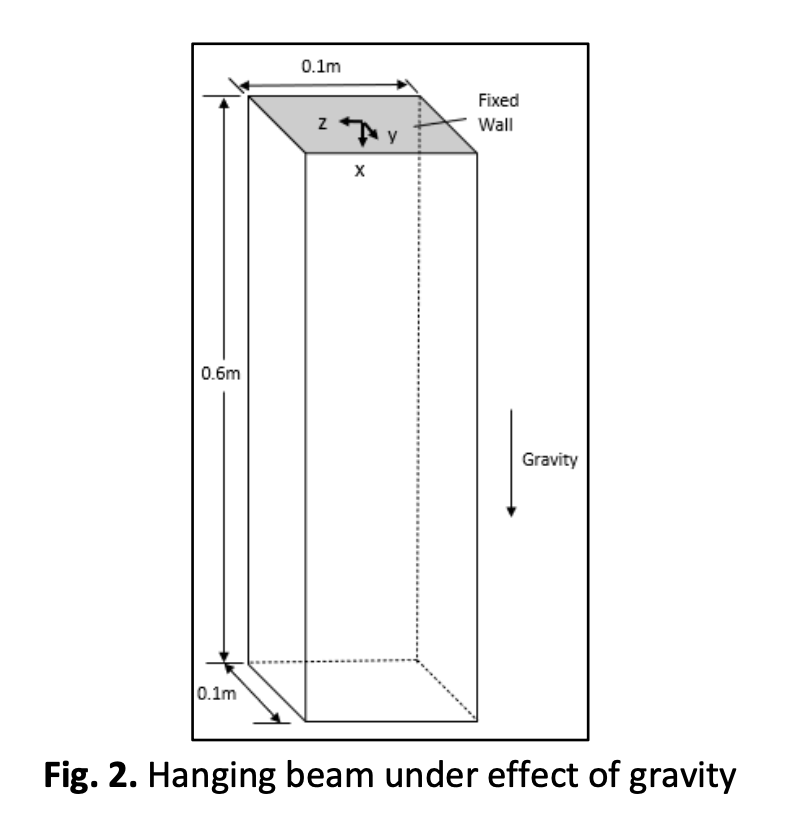

The use of lattice spring model (LSM) in modelling composite material is verified using static and dynamic loading test cases. The LSM results are compared against those from finite element method (FEM) implemented in ANSYS. Simple cubic (SC) lattice structure is employed in the LSM to model 3D solid body deformation. The material symmetry used to model composite material is orthotropic. In the current preliminary study, good agreement is found between the LSM and FEM results.