The Effect of Triangular Cavity Shape on the Hybrid Microchannel Heat Sink Performance

DOI:

https://doi.org/10.37934/cfdl.12.9.114Keywords:

Thermal management, Convective heat transfer, Hybrid microchannel heat sink, Triangular cavity, Performance factor, Pumping powerAbstract

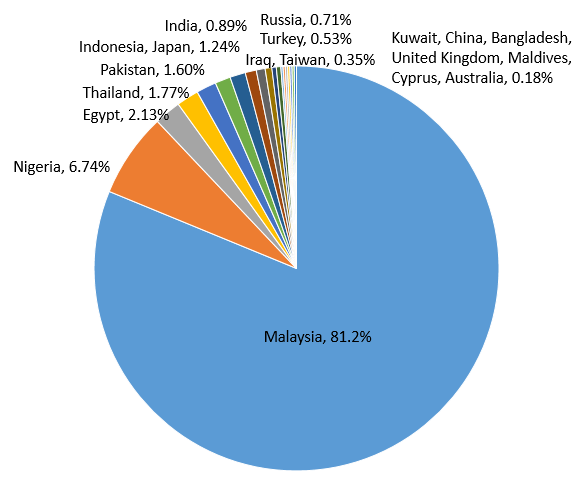

Rapid development in the electronic industry witnesses many tremendous advanced technologies which work with high power density. As a result, an advanced cooling technique, namely, microchannel heat sink (MCHS) is required to fulfil the current cooling demand due to unpredicted increment of power density in a high-density microchip. A microchannel heat sink performance can be enhanced by improving the working fluid properties and or improving the design of cooling passage that contributes to the augmentation of heat transfer rate. In this paper, the optimization of hydrothermal performance was conducted by studying the effect of triangular cavity pitch location (Cavity 1, CV1: 60 µm; Cavity 2, CV2: 100 µm; Cavity 3, CV3: 140 µm) on fluid flow and heat transfer characteristic in the hybrid microchannel heat sink (Triangular cavity with rectangular rib microchannel heat sink, TC-RR MCHS). The result revealed that the TC-RR MCHS with the triangular cavity pitch location of 140 µm (CV3) showed superior performance over other pitch locations (CV1 and CV2) for all the Reynolds number (Re number). The optimum Performance Factor, , achieved by CV3 pitch location was 1.76 at Re number of 350. It indicates that the proposed design with CV3 is suitable for the technology that requires less pumping power consumption