Preparation of Bioink for Hydrogel Printing in Additive Manufacturing

DOI:

https://doi.org/10.37934/mjcsm.12.1.4350Keywords:

Additive Manufacturing, Bioprinting, HydrogelAbstract

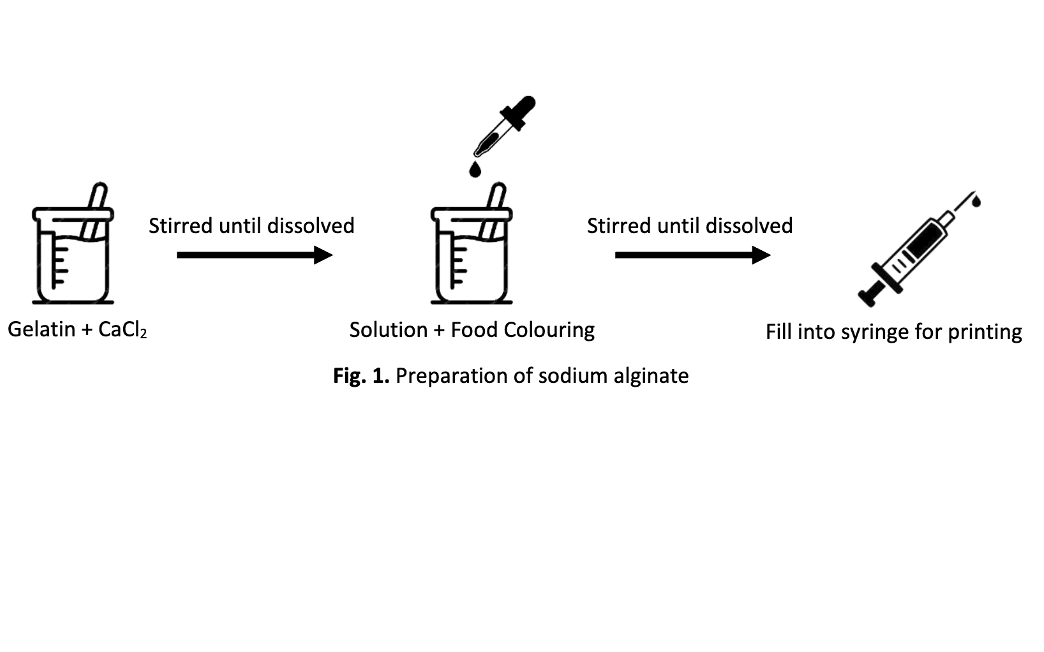

Three-dimensional (3D) bioprinting is a significant advancement in tissue engineering as it enables the printing of relevant scaffolds used for tissue repair and treating conditions like organ failure. However, printing soft biomaterials has been a major challenge due to their susceptibility to gravitational collapse. A GelPrint Scaffold method for hydrogel preparation was developed to overcome the obstacle. It provides a solution by holding the soft biomaterials in a gelatin slurry support bath during printing, polymerizing the biomaterial for crosslinking for a well-structured scaffold build-up. The bioprinting process of the alginate scaffold was conducted using a customized liquid extruder attached to a commercial 3D printer. The pores of the crosslinked printed structures were measured to identify the susceptibility of the scaffold for cell culture. The results demonstrated that the approach successfully fabricated 3D printed alginate scaffolds, approximately 90% similar to the Computer-aided design (CAD) design dimension, which has the potential to be applied to various tissue engineering applications. These scaffolds hold great promise for various tissue engineering applications, indicating the potential of the adapted bioink preparation method in advancing the field of regenerative medicine.

Downloads