Production of Porous Copper via Uniaxial Compaction Assisted by Potassium Chloride as a Space Holder

DOI:

https://doi.org/10.37934/mjcsm.16.1.125139Keywords:

Porous Copper, Powder Metallurgy, Space Holder, Scanning Electron Microscopy, Potassium Chloride (KCl), Porosity Control, Uniaxial CompactionAbstract

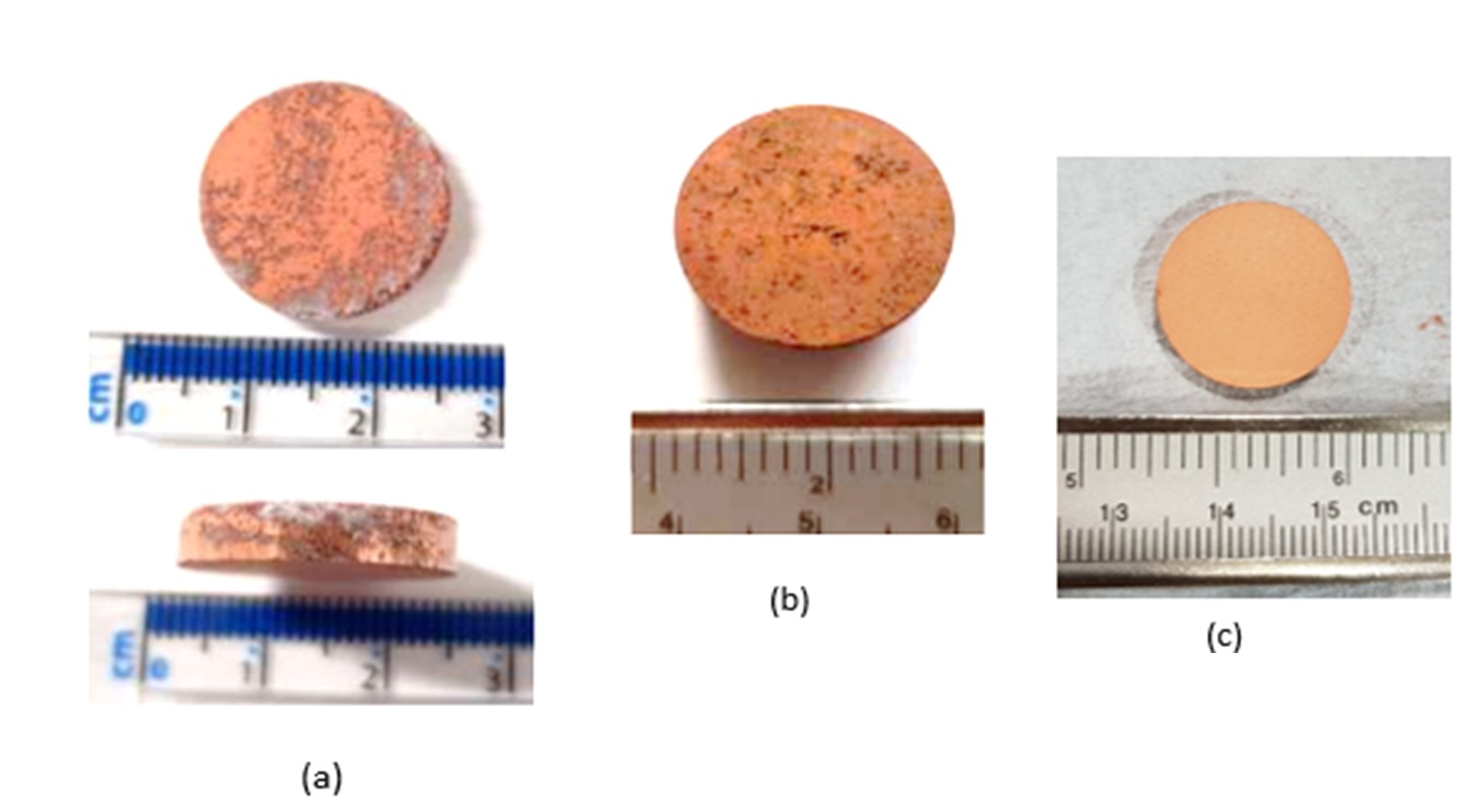

Porous metal fabrication has garnered considerable attention for its cost-effectiveness, lightweight properties, and desirable characteristics such as mechanical strength, thermal management, acoustic insulation, and fluid permeability, making it valuable across industries like automotive, biomedical, aerospace, and electronics. Among these, porous copper stands out for applications like heat sinks in portable electronic devices due to its high specific surface area and excellent permeability. However, the challenge lies in achieving precise control over porosity and mechanical properties. This study explores the fabrication of porous copper using powder metallurgy, employing uniaxial compaction and potassium chloride (KCl) as a space holder. KCl was chosen for its chemical inertness and efficient dissolution properties. Copper-KCl mixtures with KCl content ranging from 10% to 30% were compacted at pressures between 9.81 MPa and 19.61 MPa, sintered at 700°C under an argon atmosphere, and subjected to a dissolution process at 50°C for 5 hours. Porosity was determined using a gravimetric method based on Archimedes’ principle, while X-ray Fluorescence (XRF) analysis assessed the efficiency of KCl removal. Uniaxial compression testing revealed the influence of porosity and compaction pressure on the mechanical strength of the samples. The findings highlight the potential of tailored porous copper for lightweight, high-performance applications requiring controlled thermal and mechanical properties.

Downloads