Effect of Water Content in Raw Material Mixtures on the Proximate, Physical, and Mechanical Properties of Coconut Shell Charcoal Briquettes Produced with a Screw Extruder Machine

DOI:

https://doi.org/10.37934/mjcsm.16.1.258273Keywords:

Water content, proximate, physical, mechanicalAbstract

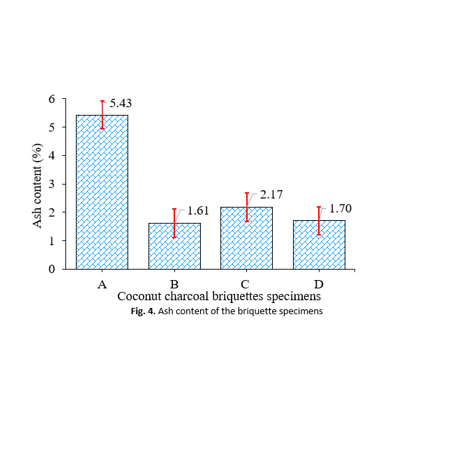

Coconut shell charcoal briquettes offer a green and productive energy option. However, past studies have looked at single factors without exploring how water levels in raw material mixes affect briquette performance. This research aims to fill this gap by looking at how different water contents in the raw material mixture (44.9%, 46.5%, 49%, and 52.5% for Specimens A, B, C, and D) impact the quality of briquettes made with a screw extruder machine. To produce briquettes, the process involves several steps: preparing coconut shell charcoal powder, mixing this powder with a binder (5% tapioca), adjusting water content to reach the desired levels, blending the mixture thoroughly, forming the mixture using a screw extruder machine, and drying the resulting briquettes. The study used established techniques to assess proximate properties, physical characteristics, and mechanical performance (compressive strength and friability). The findings demonstrate that Specimen C, displaying a water content of 49%, showed the most favourable overall performance. The data indicates the highest fixed carbon content at 71.80%, a calorific value of 7,102 Cal/g, and a density of 0.57 g/cm³ while also showing the minimum friability at 9.43%. Conversely, Specimen D, exhibiting the highest water content at 52.5%, showed the lowest friability at 40.19% and a compressive strength of 14.58 kg/cm². The results of this study indicate that the water content of 49% significantly improves briquette quality, achieving a balance between structural integrity and combustion efficiency. This study offers essential findings on enhancing briquette production processes, creating high-quality briquettes for domestic and international markets, and supporting the sustainable use of coconut shell waste.Downloads