Tensile Properties Degradation of Thermally Aged NR/EPDM Blend and Nanocomposites for Engine Mounting

DOI:

https://doi.org/10.37934/mjcsm.2.1.2130Keywords:

Natural Rubber, Ethylene Propylene Diene Monomer, Graphene Nanoplatelets, Thermal Cycles, Tensile PropertiesAbstract

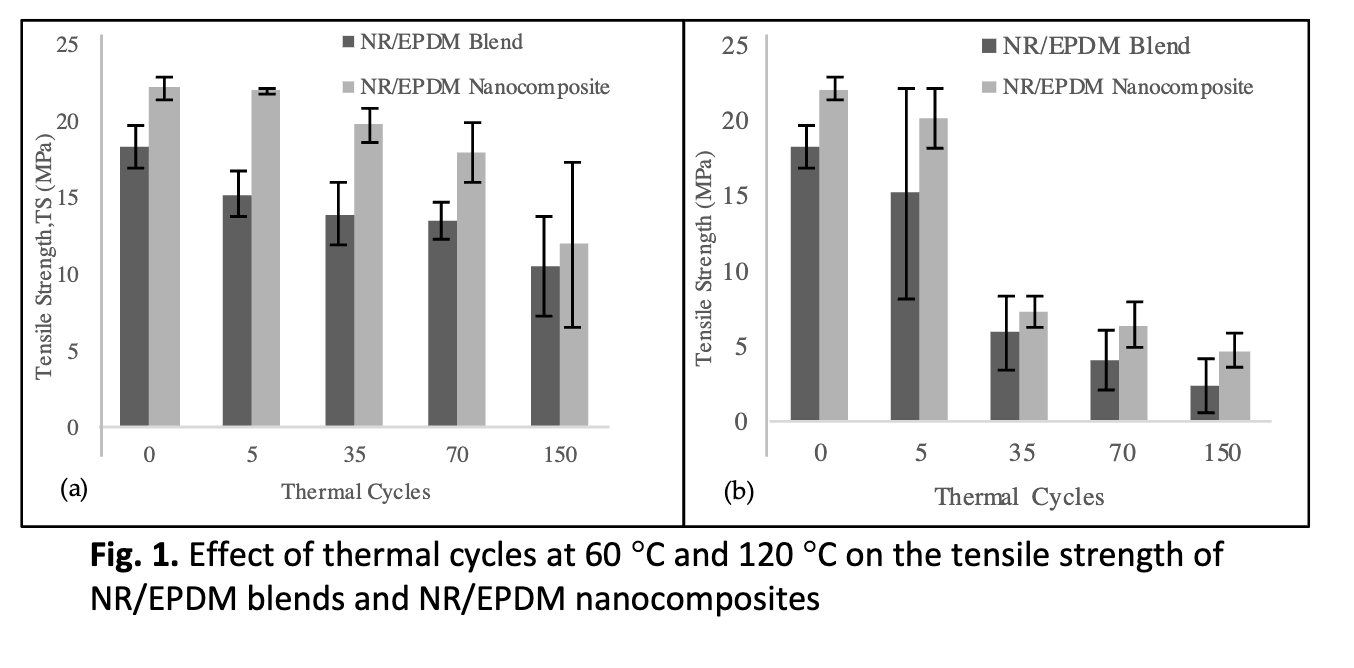

Nowadays, NR/EPDM have drawn great attention to most researchers to be utilized in an engine mounting. In service, majority of structures and components are subjected to service condition such as heat, liquids and stress of dynamic loading. This research is an effort to compare the thermal effects on physical and mechanical properties of NR/EPDM blend and NR/EPDM filled graphene nanoplatelets (GNPs) for the potential usage in the engine mounting. The blends and nanocomposites were prepared through a melt compounding using a Banbury Internal Mixer, exposed to thermal cycles and tensile tested. The materials were heated alternately for 10 minutes at 60? and 120? for 0, 35, 70 and 150 cycles. Thermally aged NR/EPDM nanocomposites showed higher performance under tensile stress if compared to NR/EPDM blend. The tensile strength and elastic modulus were consistently 40% higher than the strength of the blend. This is due to the reinforcing effects of GNPs and their good interaction with the matrix. The reduction of tensile properties was due to the embrittlement effect and in line with the increase in amorphous phases from the broadening of XRD spectra. This has proven that the NR/EPDM nanocomposites can withstand thermal cycles, oils and fluctuating stress better than NR/EPDM blend and exhibited higher potential to be utilized as the engine mount material.

Downloads