Analysis of Carbon Fiber-Reinforced Polymer Composites Delamination during Vibration Assisted Trimming using Historical Data Design

DOI:

https://doi.org/10.37934/mjcsm.6.1.113Keywords:

CFRP, Vibration-assisted machining, Trimming, OptimizationAbstract

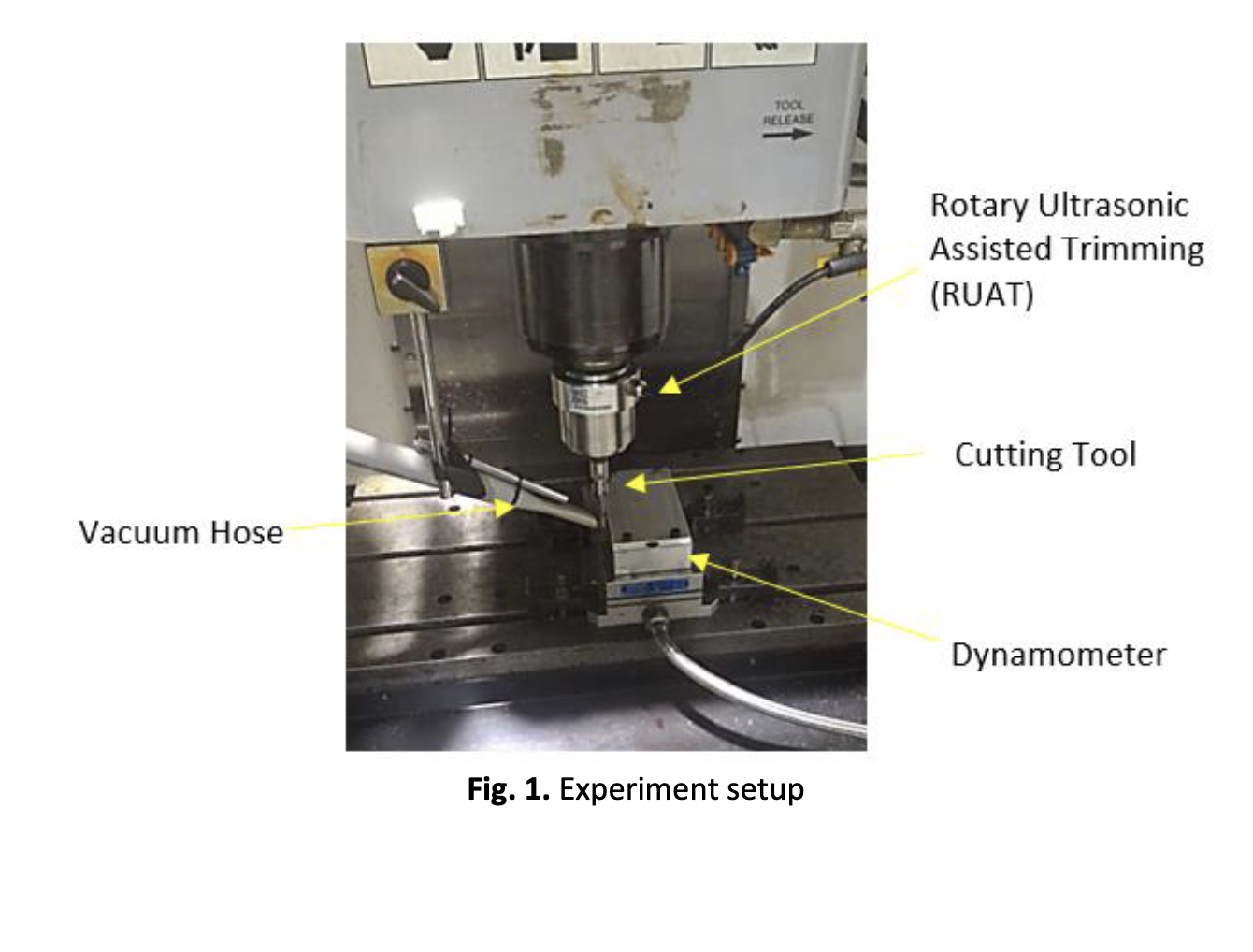

Delamination is one of the main issues during the CFRP cutting process. This problem attracts researchers to investigate to meet the stringent quality need. This paper evaluates the influence of Rotary Ultrasonic Assisted Trimming (RUAT) when slotting carbon fiber reinforced plastic (CFRP). The study investigates rotation speed, vibration amplitude, and frequency particularly. The correlation effect of these parameters is to be evaluated by response surface methodology (RSM) to identify the minimum delamination. Seventeen trials were conducted with 38 plies of multi-directional CFRP panel. The trimming quality was determined by the minimum delamination damage of the slotting area analyzed by the ImageJ software. The best slotting quality can be achieved by applying spindle speed, amplitude, and frequency of 5305 rpm, 2.75 µm, and 26.79 kHz.

Downloads