Effect of Printing Orientation and Layer Thickness on Microstructure and Mechanical Properties of PLA Parts

DOI:

https://doi.org/10.37934/mjcsm.8.1.1123Keywords:

Fused Deposition Modeling, Layer Thickness, Printing Orientation, Mechanical PropertiesAbstract

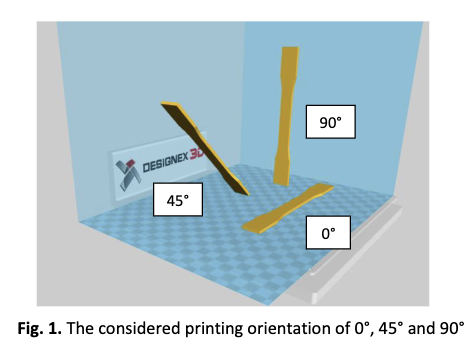

Due to the layer-by-layer printing process, additively manufactured objects frequently display directional dependencies in their structure. It affects the material properties of the fabricated parts concerning various process parameters of the machine. This paper presents the effect of layer thickness and printing orientation on the mechanical properties and microstructure of polylactic acid (PLA)3D printed parts fabricated by Fused Deposition Modeling (FDM). Computer-aided design models of a tensile and compression test specimen were created, conforming to the ASTM: D638 (Type 1 and Type IV) and ASTM D695, respectively. The microstructure was evaluated using a Scanning Electron Microscope (SEM) on the fracture surface during the tensile test and optical microscopy on the compression specimens. The finding shows that a low layer thickness setting contributes to the highest tensile strength in the 0° printing orientation, while a medium and high layer thickness results in a better tensile strength for a 45° and 90° printing orientation. Therefore, printing orientation is more influential than layer thickness in the tensile test. As for the compressive strength, the stress decreases when the layer thickness increases and the low layer thickness setting offers the highest compressive strength at all printing orientations. The microstructure shows more significant interlayer gaps, incomplete filling, and weak bonding on the cross-sectional samples of the fractured tensile surface with lower strength. The 0° printing orientation offers better tensile strength for all layer thicknesses, minimum build time, and good compressive strength compared to other printing orientations.

Downloads