Injection Moulding Parameters Effect on Fracture Toughness of Polypropylene Nanocomposite Gigantochloa Scortechinii Using Taguchi Method

DOI:

https://doi.org/10.37934/mjcsm.16.1.224234Keywords:

Fracture toughness, Injection Molding, Nanocomposites, Taguchi Method, Polypropylene Nanoclay Gigantochloa-ScortechiniiAbstract

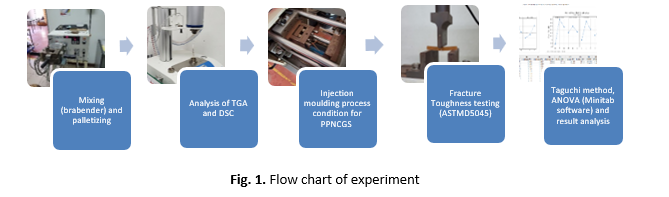

This paper presents an experimental study about injection moulding parameters effect on fracture toughness of polypropylene-nanoclay-gigantochloa-scortechinii nanocomposites with 0 wt.%, 3 wt.%, and 6 wt.% of bamboo fibre content. The selected parameters were melt temperature, packing pressure, screw speed and filling time. The composite samples were injection moulded from a material consisting of polypropylene, bamboo fibres, compatibilizer, and nanoclay. Linear Elastic Fracture Mechanics method according to ASTM D5045 was used to evaluate the fracture toughness. The experimental design was made by adopting the Taguchi Method Orthogonal Array. Analysis of variance was used to determine the most contributing parameters and the plot of main effect diagrams were used to define the optimum factor values. The results showed that the composite with 6 wt.% bamboo fibres had the highest KIc value of 18.188 MPa.m1/2, while the nanocomposite without bamboo fibres had the lowest KIc value, 11.693 MPa.m1/2. It was found that the fracture toughness increased with the addtion of bamboo fibre. As for the samples made of 6 wt.%, the melting temperature was the most influential factor affecting the fracture toughness, but for samples made of 3 wt.% the packing pressure is the decisive factor. The combination of 175°C melt temperature, 50% packing pressure, 40% screw speed and 2 seconds filling time results in the sample with 3 wt.%, bamboo fibre content. The combination of 170°C melt temperature, 45% packing pressure, 30% screw speed and 2 seconds filling time, were the optimum values for the 6 wt.%, bamboo fibre content sample that produced the highest fracture toughness for this formulation. The knowledge from this research was useful for manufacturing industries that using injection molding process to produce their product, by using this new type of material. On top of that, the use of organic and natural materials such as bamboo fibres can acellerate the efforts in reducing the environmental footprint.Downloads