A Study of Fracture Toughness Towards Polypropylene Nanoclay Nanocomposites with Different Bamboo Fiber Loading

DOI:

https://doi.org/10.37934/mjcsm.16.1.140149Keywords:

Fracture toughness, three-point bending test, bamboo fiber, polypropylene, nanoclayAbstract

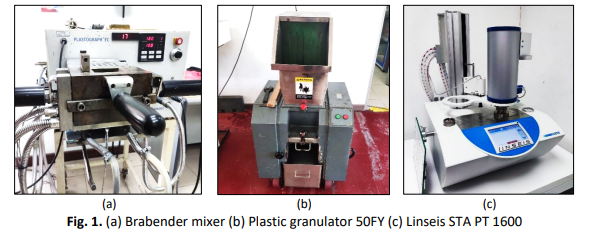

The development of sustainable, high-performance materials is crucial to meet the demands for eco-friendly and durable composites in various industries. Polypropylene nanoclay composites reinforced with natural fibres, such as bamboo, offer a promising alternative due to their improved mechanical properties and environmental benefits. However, the fracture toughness of these polypropylene nanoclay composites with varying bamboo fibre loadings remains insufficiently studied, particularly in terms of how different fibre concentrations impact the material's resistance to crack propagation and overall mechanical integrity under stress. Therefore, this paper was published to elucidate the findings of fracture toughness analysis of polypropylene nanoclay bamboo fibre nanocomposite that consist of 0 wt.%, 3 wt.% and 6 wt.% of bamboo fibre loadings. This research aims to systematically investigate how different bamboo fibre loadings affect the fracture toughness of polypropylene nanoclay nanocomposites. The study will assess the composite’s behaviour under fracture and determine the optimal fibre loading for maximizing fracture toughness while maintaining lightweight and eco-friendly characteristics. The sample was moulded by an injection moulding procedure, with compounded samples of polypropylene, bamboo fibre, polypropylene-graft-maleic anhydride (compatibilizer), and nano clay. The optimal injection moulding temperature for the sample was determined using Differential Scanning Calorimetry and Thermogravimetric Analysis. The Mode 1 plane strain fracture toughness was evaluated using the Linear Elastic Fracture Mechanics approach in accordance with ASTM D5045. As for the results, the composite with 6 wt.% bamboo fibre has the highest value of the average fracture toughness with 62.9743 MPa.m1/2, as compared with sample of 3 wt.% bamboo fibre, which is 59.6709 MPa.m1/2. Meanwhile, the sample without the presence of bamboo fibre has lowest average fracture toughness at 43.260 MPa.m1/2. In conclusion, the bamboo fibre has proven its potential to be a promising reinforcing agent, and it can be used in any suitable applications, such as automotive components, building materials and packaging solutions.Downloads