Utilization of Rice Husk Fiber Blended Recycled Polyethylene Terephthalate for Manufacturing RHF/R-PET Polymer Composites

DOI:

https://doi.org/10.37934/mjcsm.16.1.245257Keywords:

Rice husk fiber, R-PET, polymer, composite, tensile strengthAbstract

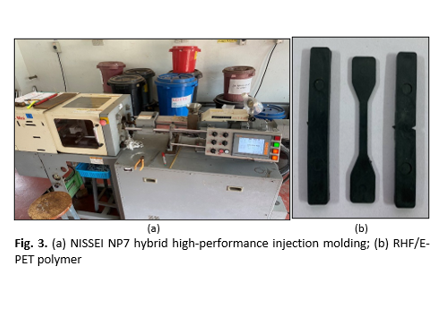

In response to the growing global awareness of the environmental crisis, a natural fiber-blended polyethylene material is being developed for the production of polymer composites. This research focuses on harnessing abundant waste materials such as Rice Husk Fiber (RHF) and Recycled Polyethylene Terephthalate (R-PET) in Malaysia to create RHF/R-PET polymer composites. The main goal of this study is to identify and characterize the optimal composition of RHF/PET polymer composites suitable for deck panel applications. The research investigates various composition ratios of RHF fibers, ranging from 5 to 20 wt/w% when blended with R-PET sourced from recycled bottles produced at Angkasa Kowaris Plastics Sdn Bhd. This study holds significant importance in the development of an environmentally friendly polymer composite material, utilizing abundant natural resources approaching RHF fibers found in Malaysia. The study includes physical and mechanical testing of samples with different RHF fiber composition ratios. The findings reveal that the ideal combination for producing polymer composites for deck panels is achieved at a 20 wt/wt% ratio of RHF/R-PET. This composition provides good matrix bonding between RHF and R-PET with density and porosity at 1.043 g/cm3 and 0.076%, respectively. It also exhibits a maximum tensile strength of 12.53 MPa, exerting a force at 138.90 N with a maximum stress of 14.8 N/mm2. Additionally, 20 wt/wt% gives a higher Young’s modulus value at 12.12 MPa. For bending strength 20 wt/wt% was achieved at 19.78 N with a maximum stress of 10.45 MPa. The incorporation of RHF fibers in fiber-reinforced composite applications offers economic benefits due to their renewability, biodegradability, and cost-effectiveness compared to manufactured fibers. This approach has the potential to contribute significantly to Malaysia's economy by providing a waste material alternative to raw materials while maximizing the utilization of RHF fibers and R-PET waste resources.Downloads