The Effects Strength & Density of Autoclaved Aerated Concrete Containing Semiconductor Electronic Molding Resin Waste (AAC-SEMRW) on Partition Panel Application

DOI:

https://doi.org/10.37934/mjcsm.16.1.316327Keywords:

Semiconductor, resin waste, autoclaved aerated concrete (AAC), strength, partition panelAbstract

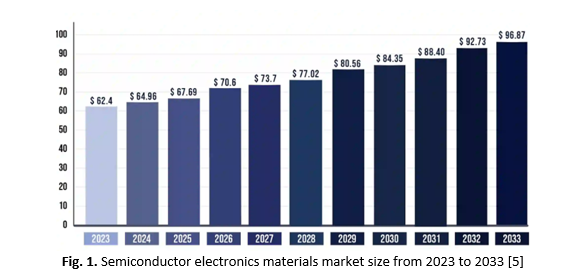

Semiconductor Electronic Molding Resin Waste (SEMRW) a byproduct of IC package manufacturing, is widely utilized in the electronics industry. However, recycling this material in an efficient and sustainable manner remains critical, especially for promoting eco-friendly practices in construction. This study focuses on repurposing SEMRW autoclaved aerated concrete (AAC) for partition panel applications. Resin waste obtained from STMicroengineering Sdn Bhd was finely ground to a particle size of 0.1 ± 0.01 mm and incorporated into the AAC mixture in varying percentages—0%, 5%, 10%, 15%, 20%, 25%, and 30% containing with standard amounts of cement, quartz sand, water, and a 3% aluminum paste. The prepared mixtures were molded and curing into autoclaved machine for 4 hours. Experimental results indicated a reduction in both water absorption and pore formation as SEMRW content increased. Microstructural analysis using Scanning Electron Microscopy (SEM) revealed a more compact structure with higher RW proportions. The AAC-SEMRW composition containing 20% resin waste achieved the highest compressive strength values, with 7.29 MPa after 8 hours of curing in Autoclaved Machine. Furthermore, this composition exhibited the greatest residual compressive strength (8.22%) when exposed to elevated temperatures. Based on these findings, the 20% SEMRW formulation is identified as the optimal mixture, offering improvements in water absorption, compressive strength, and thermal resistance. This research contributes to sustainable waste management, provides an innovative green construction material, and enhances the performance of AAC for partition panel applications, reflecting a significant advancement in construction technology.Downloads