Life Cycle Assessment of Potassium Lysinate for Biogas Upgrading

DOI:

https://doi.org/10.37934/progee.22.1.2939Keywords:

Life cycle assessment, Global warming potential, Acidification potential, Eutrophication potential, Potassium lysinateAbstract

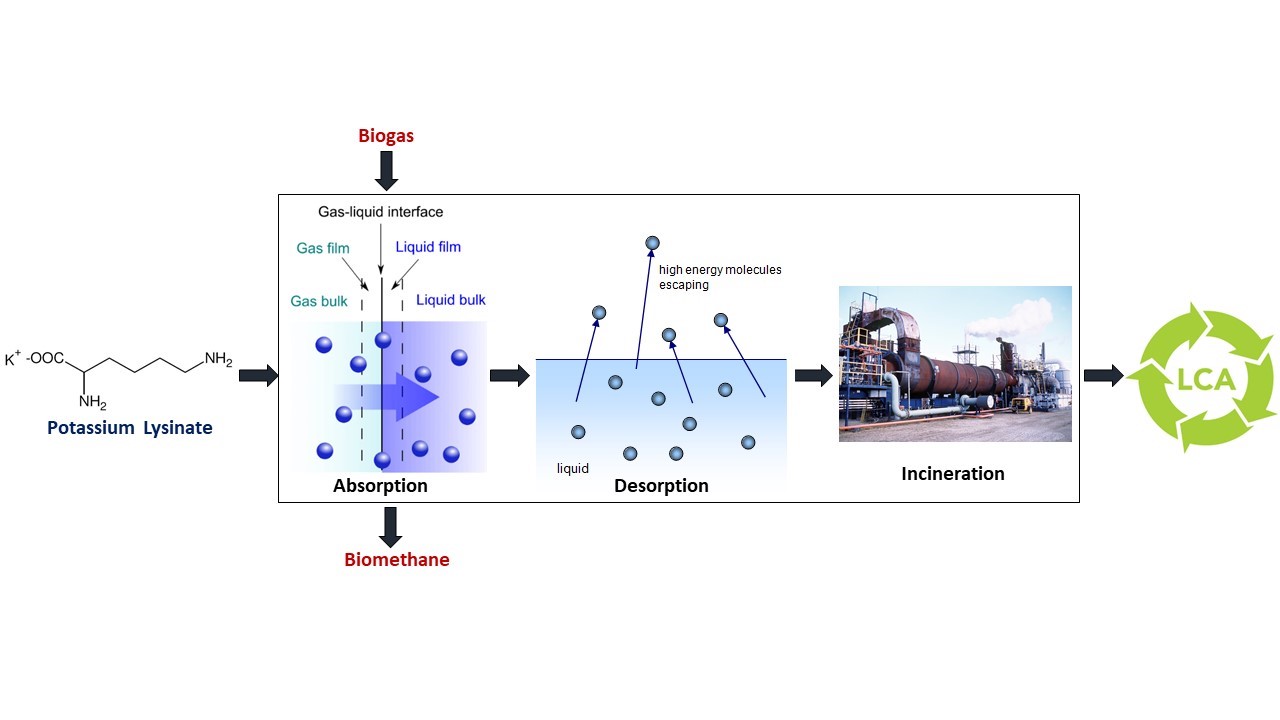

Monoethanolamine solvent (MEA) is a common solvent used in biogas upgrading plant for carbon dioxide (CO2) and hydrogen sulfide (H2S) removal. However, it has some downsides such as corrosive, high toxicity, and promotes products degradation. Alternatively, amino acid-based solvents such as potassium lysinate (LysK) have been found to have good absorption performance. It is also claimed to be more environmentally friendly as it is less toxic and has a good biodegradability. However, its actual environmental impact for the application of biogas upgrading has not been quantified in a detailed manner. Therefore, in this study, the environmental impact of LysK solvent is quantified from gate to grave in terms of Global Warming Potential (GWP), Acidification Potential (AP) and Eutrophication Potential (EP) using life cycle assessment (LCA) approach. The process was simulated using process simulator, SuperPro Designer version 10 to obtain the input-output data. LysK solvent has a low heat of absorption, which could result in lower CO2 emissions during the biogas upgrading process. However, due to its energy-intensive nature, the incineration process significantly contributed to GWP, AP, and EP. There were also emissions of NOx and SO2 from the flue gas of the incinerator. The findings of this research provide some insight on the environmental impact of utilising LysK for biogas upgrading.

References

A.I. Adnan, M.Y. Ong, S. Nomanbhay, K.W. Chew, and P.L. Show, Technologies for biogas upgrading to biomethane: a review, Bioengineering 6(4) (2019) 92. https://doi.org/10.3390/bioengineering6040092.

Environmental and Energy Study Institute (EESI), Fact Sheet: Biogas: Converting Waste to Energy, EESI, 2017. https://www.eesi.org/papers/view/fact-sheet-biogasconverting-waste-to-energy.

J. Sarika, Global potential of biogas, World Biogas Association, 2019. https://www.worldbiogasassociation.org/wp-content/uploads/2019/07/WBA-globalreport-56ppa4_digital.pdf.

L.C. David, Explained: Greenhouse gases, MIT News Office, 2017. Retrieved November 05, 2020, from https://news.mit.edu/2017/explained-greenhouse-gases-0130.

V. Paolini, F. Petracchini, M. Segreto, L. Tomassetti, N. Naja and A. Cecinato, Environmental impact of biogas: A short review of current knowledge, Journal of Environmental Science and Health, Part A, 53(10) (2018) 899-906. https://doi.org/10.1080/10934529.2018.1459076.

Q. Sun, H. Li, J. Yan, L. Liu, Z. Yu, and X. Yu, Selection of appropriate biogas upgrading technology-a review of biogas cleaning, upgrading and utilisation, Renewable and Sustainable Energy Reviews 51 (2015) 521-532. https://doi.org/10.1016/j.rser.2015.06.029.

P.G. Kougias, L. Treu, D.P. Benavente, K. Boe, S. Campanaro and I. Angelidaki, Ex-situ biogas upgrading and enhancement in different reactor systems, Bioresource Technology 225 (2017) 429-437. https://doi.org/10.1016/j.biortech.2016.11.124.

K. Starr, X. Gabarrell, G. Villalba, L. Talens and L. Lombardi, Life cycle assessment of biogas upgrading technologies, Waste Management, 32(5) (2012) 991-999. https://doi.org/10.1016/j.wasman.2011.12.016.

I.U. Khan, M.H.D. Othman, H. Hashim, T. Matsuura, A.F. Ismail, M. Rezaei-DashtArzhandi and I.W. Azelee, Biogas as a renewable energy fuel - A review of biogas upgrading, utilization and storage, Energy Conversion and Management 150 (2017) 277-294. https://doi.org/10.1016/j.enconman.2017.08.035.

C. Florio, G. Fiorentino, F. Corcelli, S. Ulgiati, S. Dumontet, J. Güsewell, and L. Eltrop, A life cycle assessment of biomethane production from waste feedstock through different upgrading technologies, Energies 12(4) (2019) 718. https://doi.org/10.3390/en12040718.

A. Rosli, A.L. Ahmad, J.K. Lim and S.C. Low, Advances in liquid absorbents for CO2 Capture: A review, Journal of Physical Science 28(Supp. 1) (2017) 121–144. https://doi.org/10.21315/jps2017.28.s1.8.

M. Castro-Puyana, M.L. Marina and M. Plaza, Water as green extraction solvent: principles and reasons for its use, Current Opinion in Green and Sustainable Chemistry 5 (2017) 31-36. https://doi.org/10.1016/j.cogsc.2017.03.009.

M.E. Hamzehie and H. Najibi, Experimental and theoretical study of carbon dioxide solubility in aqueous solution of potassium glycinate blended with piperazine as new absorbents, Journal of CO2 Utilization 16 (2016) 64-77. https://doi.org/10.1016/j.jcou.2016.06.003.

T.T. Vo, D.M. Wall, D. Ring, K. Rajendran, J.D. Murphy, Techno-economic analysis of biogas upgrading via amine scrubber, carbon capture and ex-situ methanation, Applied Energy 212 (2018) 1191-1202. https://doi.org/10.1016/j.apenergy.2017.12.099.

M.H. Nematollahi and P.J. Carvalho, Green solvents for CO2 capture, Current Opinion in Green and Sustainable Chemistry 18 (2019) 25-30. https://doi.org/10.1016/j.cogsc.2018.11.012.

S. Shen, Y. Zhao, Y. Bian, Y. Wang, H. Guo and H. Li, CO2 absorption using aqueous potassium lysinate solutions: vapor–liquid equilibrium data and modelling, The Journal of Chemical Thermodynamics 115 (2017) 209-220. https://doi.org/10.1016/j.jct.2017.07.041.

V. Sang Sefidi and P. Luis, Advanced amino acid-based technologies for CO2 capture: A review, Industrial & Engineering Chemistry Research 58(44) (2019) 20181-20194. https://doi.org/10.1021/acs.iecr.9b01793.

S. Yan, Q. He, S. Zhao, H. Zhai, M. Cao and P. Ai, CO2 removal from biogas by using green amino acid salts: Performance evaluation, Fuel Processing Technology 129 (2015) 203-212. https://doi.org/10.1016/j.fuproc.2014.09.019.

H. Suleman, A.S. Maulud and Z. Man, Carbon dioxide solubility in aqueous potassium lysinate solutions: high pressure data and thermodynamic modelling, Procedia Engineering 148 (2016) 1303-1311. https://doi.org/10.1016/j.proeng.2016.06.543.

J.B. Guinée and E. Lindeijer (Eds.), Handbook on life cycle assessment: operational guide to the ISO standards (Vol. 7), Springer Science & Business Media, 2002.

G. Hu, K.H. Smith, Y. Wu, K.A. Mumford, S.E. Kentish, G.W. Stevens, Carbon dioxide capture by solvent absorption using amino acids: A review, Chinese Journal of Chemical Engineering 26(11) (2018) 2229-2237. https://doi.org/10.1016/j.cjche.2018.08.003.

D.M.M. Yacout, M.A. Abd El-Kawi and M.S. Hassouna, Cradle to gate environmental impact assessment of acrylic fiber manufacturing, The International Journal of Life Cycle Assessment 21(3) (2016) 326-336. https://doi.org/10.1007/s11367-015-1023-3.

B. Morero, E. Groppelli and E.A. Campanella, Life cycle assessment of biomethane use in Argentina, Bioresource Technology 182 (2015a) 208-216. https://doi.org/10.1016/j.biortech.2015.01.077.

B. Morero, M.B. Rodriguez and E.A. Campane lla, Environmental impact assessment as a complement of life cycle assessment. Case study: Upgrading of biogas, Bioresource Technology 190 (2015b) 402-407. https://doi.org/10.1016/j.biortech.2015.04.091.

F. Ardolino, F. Parrillo and U. Arena, Biowaste-to-biomethane or biowaste-to-energy? An LCA study on anaerobic digestion of organic waste, Journal of Cleaner Production 174 (2018) 462-476. https://doi.org/10.1016/j.jclepro.2017.10.320.

F. Ardolino, G.F. Cardamone, F. Parrillo, and U. Arena, Biogas-to-biomethane upgrading: A comparative review and assessment in a life cycle perspective, Renewable and Sustainable Energy Reviews 139 (2021) 110588. https://doi.org/10.1016/j.rser.2020.110588.

C.K. Kuan, D.C.Y. Foo, R.R. Tan, S. Kumaresan and R.A. Aziz, Streamlined life cycle assessment of residue utilization options in Tongkat Ali (Eurycoma longifolia) water extract manufacturing process, Clean Technologies and Environmental Policy 9(3) (2007) 225-234. https://doi.org/10.1007/s10098-007-0088-5.

G.K.X. Poh, I.M.L. Chew and J. Tan, Life cycle optimization for synthetic rubber glove manufacturing, Chemical Engineering & Technology 42(9) (2019) 1771-1779. https://doi.org/10.1002/ceat.201800476.

R. Sitthikhankaew, S. Predapitakkun, R.W. Kiattikomol, S. Pumhiran, S. Assabumrungrat and N. Laosiripojana, Comparative study of hydrogen sulfide adsorption by using alkaline impregnated activated carbons for hot fuel gas purification, Energy Procedia 9 (2011) 15-24. https://doi.org/10.1016/j.egypro.2011.09.003.

M. Mel, A.S.H. Yong, S.I. Ihsan and R.H. Setyobudi, Simulation study for economic analysis of biogas production from agricultural biomass, Energy Procedia 65 (2015) 204-214. https://doi.org/10.1016/j.egypro.2015.01.026.

O.W. Awe, Y. Zhao, A. Nzihou, D.P. Minh and N. Lyczko, A review of biogas utilisation, purification and upgrading technologies, Waste and Biomass Valorization 8(2) (2017) 267-283. https://doi.org/10.1007/s12649-016-9826-4.

S.S. Warudkar, K.R. Cox, M.S. Wong and G.J. Hirasaki, Influence of stripper operating parameters on the performance of amine absorption systems for post-combustion carbon capture: Part I. High pressure strippers, International Journal of Greenhouse Gas Control 16 (2013) 342-350. https://doi.org/10.1016/j.ijggc.2013.01.050.

U. Guide, SuperPro ® Designer, 908, 2019: pp. 654-3866.

A.H. Kanhar, S. Chen and F. Wang, Incineration fly ash and its treatment to possible utilization: A Review, Energies 13(24) (2020) 6681. https://doi.org/10.3390/en13246681.

C. Seyler, T.B. Hofstetter and K. Hungerbuhler, Life cycle inventory for thermal treatment of waste solvent from chemical industry: a multi-input allocation model, Journal of Cleaner Production 13(13-14) (2015) 1211-1224. https://doi.org/10.1016/j.jclepro.2005.05.009.

Y. Zhao, S. Shen, Y. Bian, Y.N. Yang and U. Ghosh, CO2 solubility in aqueous potassium lysinate solutions at absorber conditions, The Journal of Chemical Thermodynamics 111 (2017) 100-105. https://doi.org/10.1016/j.jct.2017.03.024.

United Nations framework convention on climate change, Kyoto Protocol, Kyoto, 19(8), 1997.

M.Z. Hauschild, R.K. Rosenbaum and S. Olsen, Life cycle assessment, Springer, 2018.

G. Leonzio, Upgrading of biogas to bio-methane with chemical absorption process: simulation and environmental impact, Journal of Cleaner Production 131 (2016) 364-375. https://doi.org/10.1016/j.jclepro.2016.05.020.

P. Cozma, C. Ghinea, I. Mamaliga, W. Wukovits, A. Friedl and M. Gavrilescu, Environmental impact assessment of high pressure water scrubbing biogas upgrading technology, CLEAN–Soil, Air, Water, 41(9) (2013) 917-927. https://doi.org/10.1002/clen.201200303.

R.J. Hook, An investigation of some sterically hindered amines as potential carbon dioxide scrubbing compounds, Industrial & Engineering Chemistry Research 36(5) (1997) 1779-1790. https://doi.org/10.1021/ie9605589.

J.V. Holst, S.R. Kersten and K.J. Hogendoorn, Physiochemical properties of several aqueous potassium amino acid salts, Journal of Chemical & Engineering Data 53(6) (2008) 1286-1291. https://doi.org/10.1021/je700699u.

H. Knuutila, U.E. Aronu, H.M. Kvamsdal, and A. Chikukwa, Post-combustion CO2 capture with amino-acid salts, Energy Procedia 4 (2011) 1550-1557. https://doi.org/10.1016/j.egypro.2011.02.024.

National Research Council, Incineration Processes and Environmental Releases, in: Waste Incineration & Public Health, National Academies Press (US), 2002.

Explosion Power, How can the electrical energy consumption of a waste incineration plant be reduced? 2002. Retrieved from: https://www.explosionpower.ch/en/how-can-the-electrical-energy-consumption-of-a-waste-incineration-plant-be-reduced/.

S. Shen, Y.N. Yang, Y. Bian and Y. Zhao, Kinetics of CO2 absorption into aqueous basic amino acid salt: potassium salt of lysine solution, Environmental Science & Technology 50(4) (2016) 2054-2063. https://doi.org/10.1021/acs.est.5b04515.

Y.C. Park, J.S. Lee, J.H. Moon, B.M. Min, D.M. Shim and H.J. Sung, Performance comparison of aqueous MEA and AMP solutions for biogas upgrading, Korean Journal of Chemical Engineering, 34(3) (2017) 921-927. https://doi.org/10.1007/s11814-016-0346-5.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2022 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.