Risk Management Framework and Practices for Boiler Operations in Malaysia

DOI:

https://doi.org/10.37934/progee.23.1.2638Keywords:

Boiler safety, Risk assessment, Bowtie risk assessment, Hazard and operability study (HAZOP), Failure mode and effect analysis (FMEA)Abstract

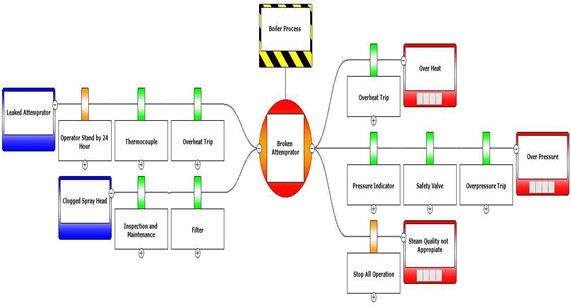

Boiler operations had a reputation for being one of the most hazardous work environments. Workers in the boiler plant face many safety risks due to the nature of the job. The work environment is often hot and noisy, consisting of several major equipment and operations involved in its process, and there is always a risk for crushing injuries, electrical shocks and burns, boiler fires and explosions, and contact with hazardous chemicals. Numerous activities performed in boiler operations are complex; these operations are hazardous and can cause accidents. This study aims to develop and propose risk management frameworks for working in a hazardous working environment at the boiler plant in Malaysia to prevent and control accidents and implement adequate safety and health management. Next, to analyze the risk factors and hazards for boiler operations based on the nature of work at the boilers in Malaysia using several methods: Bowtie Risk Assessment, Hazard and Operability Study (HAZOP), Failure Mode and Effect Analysis (FMEA). The result showed that the rate based on hazard sources in the boiler division has Extreme Risk levels (8%), High (14%), Medium (35%), and Low (43%). Risk assessment based on the type of hazard in the boiler division has risk levels ranging from high to the lowest score is the danger of Mechanical (25%), Electrical hazard (10%), chemical hazards (6%), and physical hazards (59%). The developed risk management framework with enhanced risk assessment techniques may solve the integration of sustainability aspects in boiler operations safety and risk management.

References

E.B. Woodruff, H.B. Lammers, T.F. Lammers, Steam plant operation, McGraw-Hill Education, 2017.

V. Ganapathy, Steam generators and waste heat boilers for process and plant engineers, 1st ed., CRC Press, Taylor & Francis Group, Boca Raton, 2017.

M.R. Zakaria, Risk based inspection for boiler operation in marine power plant system, Procedia Undergraduate Mechanical Engineering Research 1(4) (2019). https://myfirstthesis.c23434.net/resources/Procedia-Sept-2019.pdf.

H. Abbas, M.M. Uzair, H. Khan, S. Hussain, D.S. Topi, Designing of a fire tube boiler, Ghulam Ishaq Khan Institute of Engineering Sciences and Technology, 2020.

S. Supriyadi, F. Ramdan, Hazard identification and risk assessment in boiler division using hazard identification risk assessment and risk control (HIRARC), Journal of Industrial Hygiene and Occupational Health 1(2) (2017) 161–177. http://dx.doi.org/10.21111/jihoh.v1i2.892.

A.T. Gunawan, Implementasi fuzzy logic untuk risk assessment pada steam drum boiler di pabrik i pt. Petrokimia Gresik, Institut Teknologi Sepuluh Nopember, 2017. https://repository.its.ac.id/50839/1/02311340000015-Undergraduate_Theses.pdf.

J.L. Fuentes-Bargues, M. González-Cruz, C. González-Gaya, M. Baixauli-Pérez, Risk analysis of a fuel storage terminal using HAZOP and FTA, International Journal of Environmental Research And Public Health 14(7) (2017) 705. https://doi.org/10.3390/ijerph14070705.

A. Musyafa, H. Adiyagsa, Hazard and operability study in boiler system of the steam power plant. IEESE International Journal of Science and Technology 1(3) (2012) 1–10. https://www.ieese.org/archieves/vol1n3.1.pdf.

M.L. de Oliveira, J.E. Ruppenthal, Using the HAZOP procedure to assess a steam boiler safety system at a university hospital located in Brazil, Revista Gestão da Produção Operações e Sistemas, 13(3) (2018) 259.

T. Muafida, Analisis reliability dan safety integrity level (sil) dengan metode risk graph dan fault tree analysis (FTA) pada boiler (B-6203) Pabrik III PT. Petrokimia Gresik, Institut Teknologi Sepuluh Nopember, 2017.

A.C. Ahmad, I.N.M. Zin, M.K. Othman, N.H. Muhamad, Hazard identification, risk assessment and risk control (HIRARC) accidents at power plant, MATEC Web of Conferences 66 (2016) 00105, in: The 4th International Building Control Conference 2016 (IBCC 2016). https://doi.org/10.1051/matecconf/20166600105.

Government of Malaysia, 2011. Occupational Safety and Health Act, 1994 (Act 514). https://www.dosh.gov.my/index.php/legislation/guidelines/general/598-05-guidelines-on-occupational-safety-and-health-act-1994-act-514-2006/file.

Government of Malaysia, 2013. Factories and Machinery Act, 1967 (Act 139). https://www.dosh.gov.my/index.php/legislation/acts-legislation/26-03-factories-and-machinery-act-1967-revised-1974-acts-139/file.

Department of Occupational Safety and Health, DOSH, Guidelines for Hazard Identification, Risk Assessment and Risk Control, Ministry of Human Resource, Malaysia, 2008. https://www.dosh.gov.my/index.php/legislation/guidelines/hirarc-2/1846-01-guidelines-for-hazard-identification-risk-assessment-and-risk-control-hirarc-2008/file.

Y. Wibisono, Risk Assessment terhadap pengoperasian auxiliary steam boiler pada kapal tanker pertamina MT. Pelita, Dinamika Bahari 9(2) (2019) 2295–2306. https://doi.org/10.46484/db.v9i2.96.

K. Abror, A. Subekti, A.N. Rachmat, Analisis risiko pada boiler pabrik pengolahan tembakau dengan menggunakan metode fmea dan bow tie analysis, Politeknik Perkapalan Negeri Surabaya, 2018. http://repository.ppns.ac.id/id/eprint/2020.

Downloads

Published

How to Cite

Issue

Section

License

Copyright (c) 2023 Progress in Energy and Environment

This work is licensed under a Creative Commons Attribution-NonCommercial 4.0 International License.